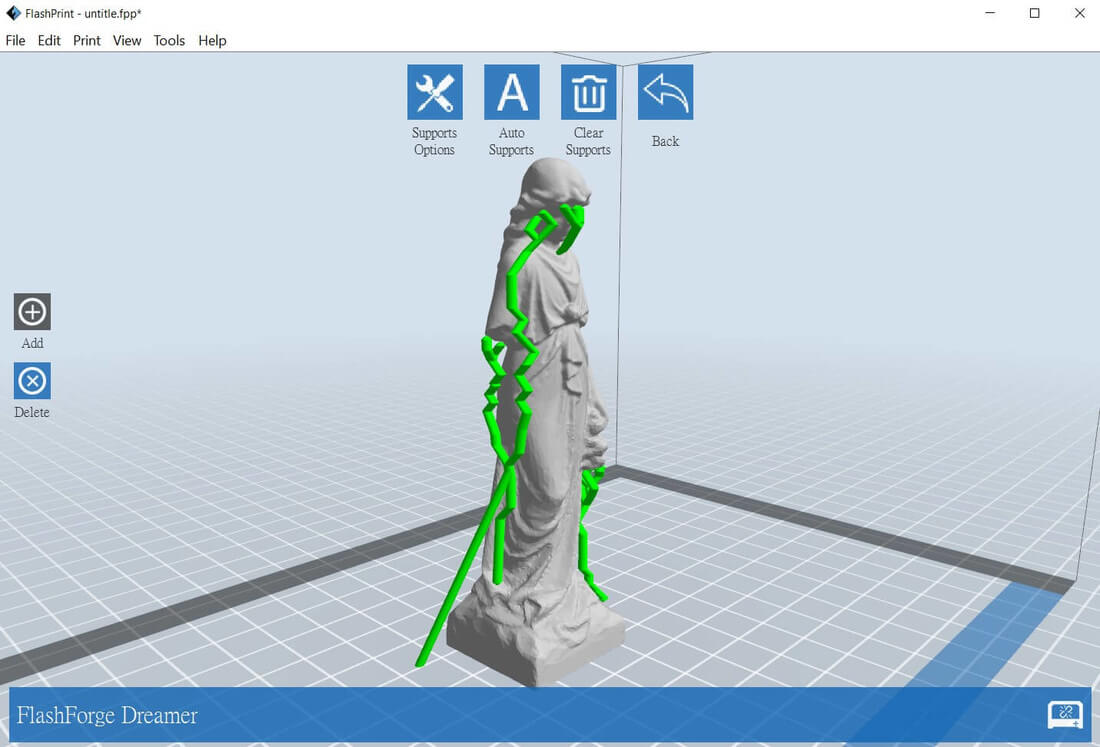

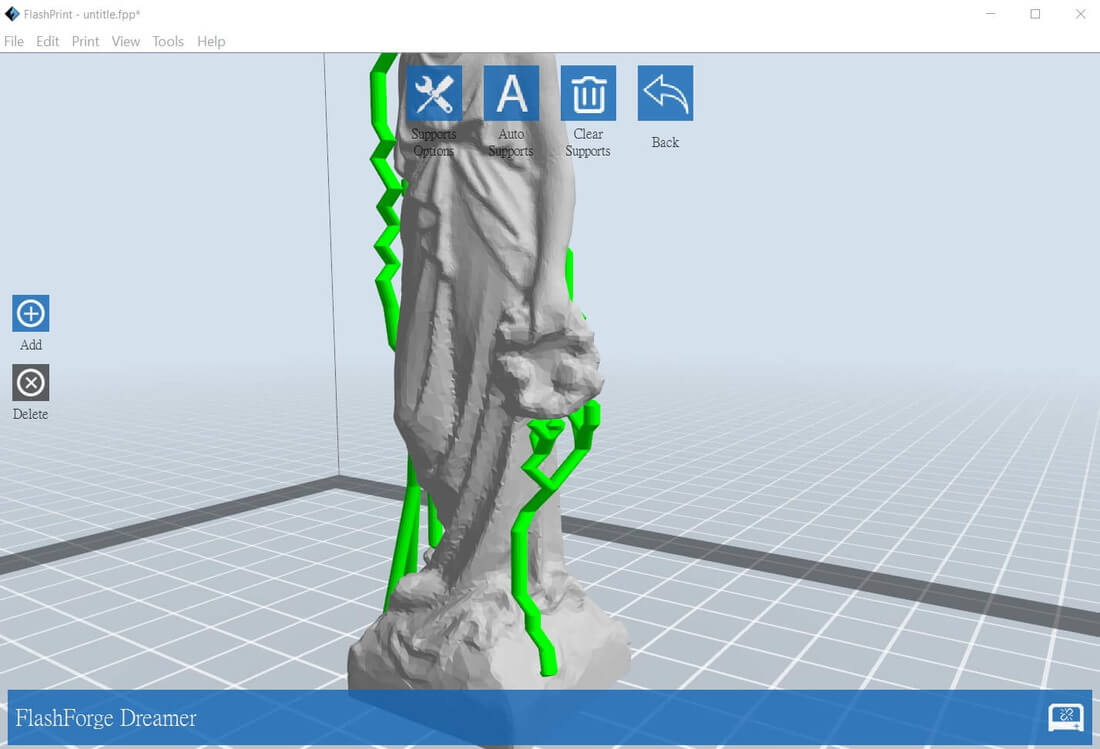

Last time we talked about the detailed settings of the treelike support in a 3D slicing software, and this time we will talk about the detailed settings of the linear support.

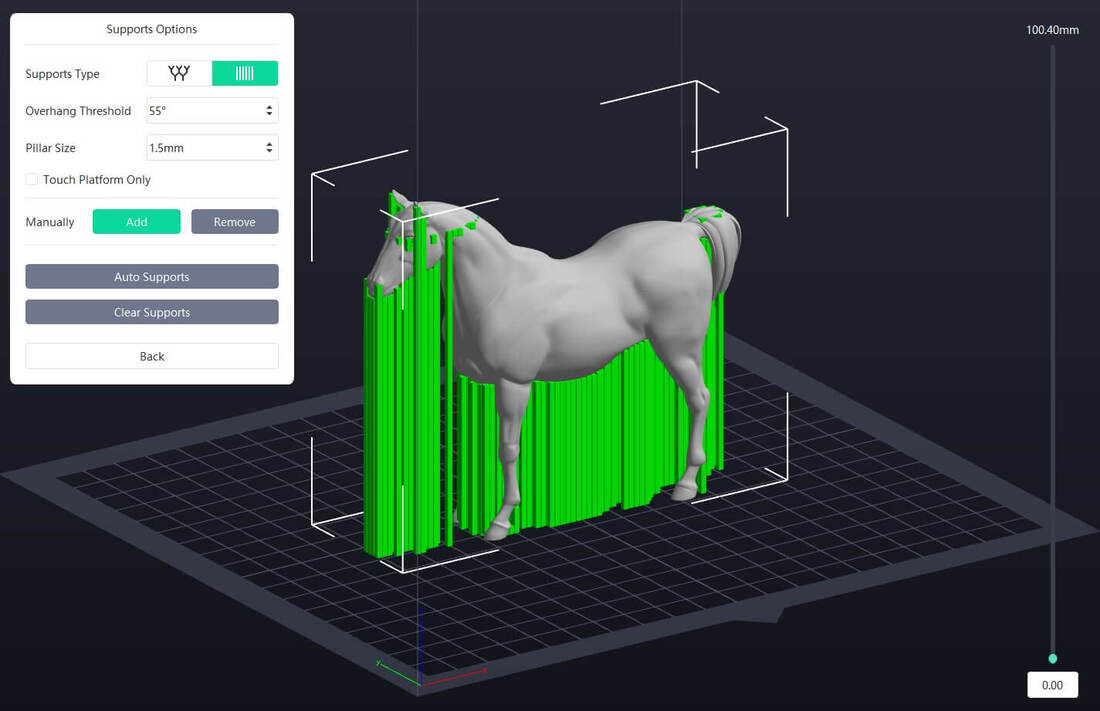

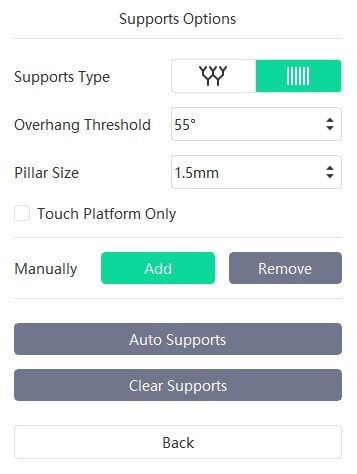

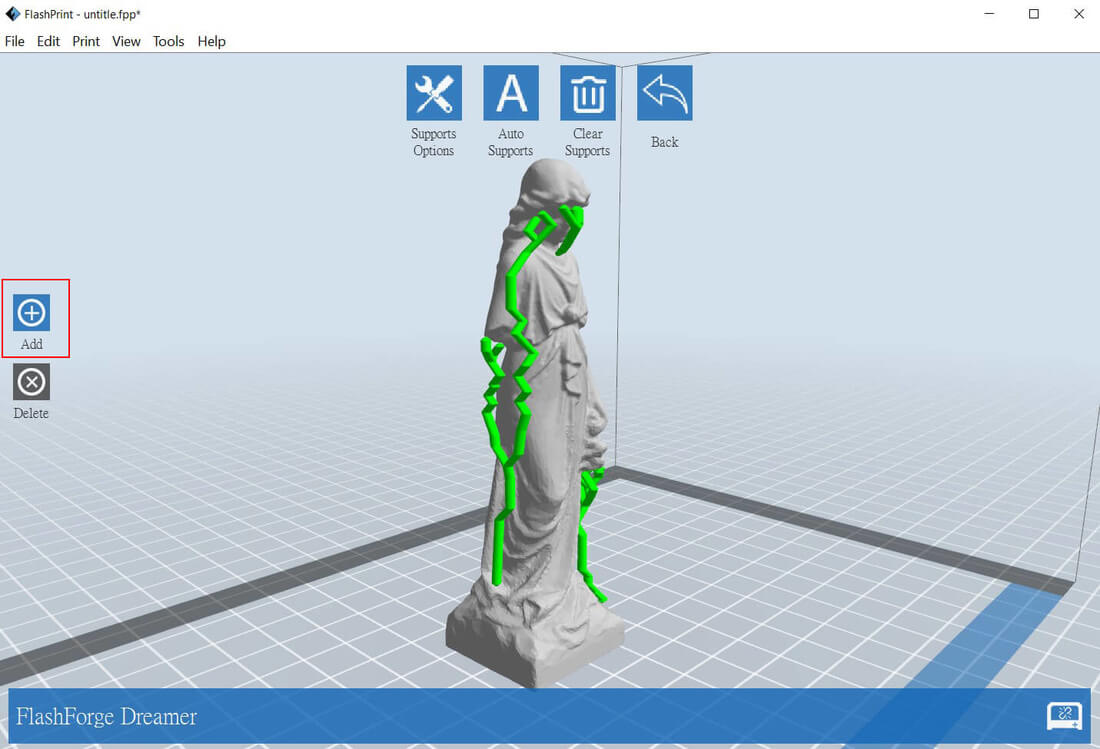

1.Overhang Threshold:

Linear support will be added if the overhang angle of the 3D model is larger than the angle you set.

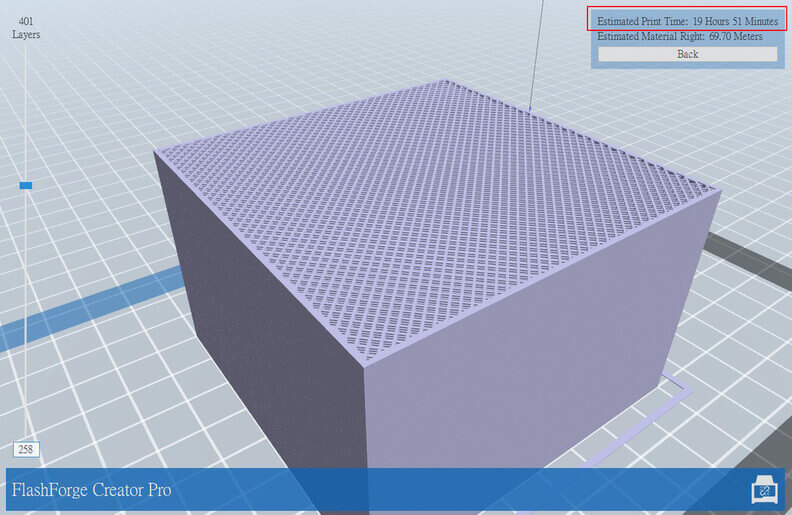

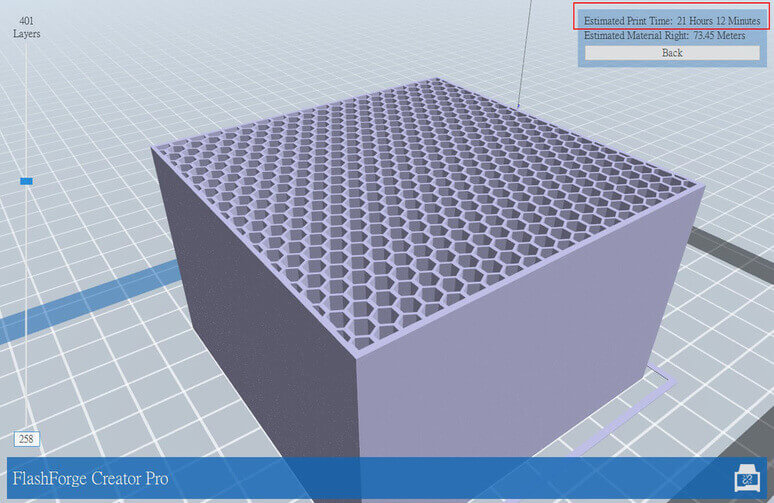

2. Pillar Size

If you want the linear support to have a higher density, you should set a smaller value.

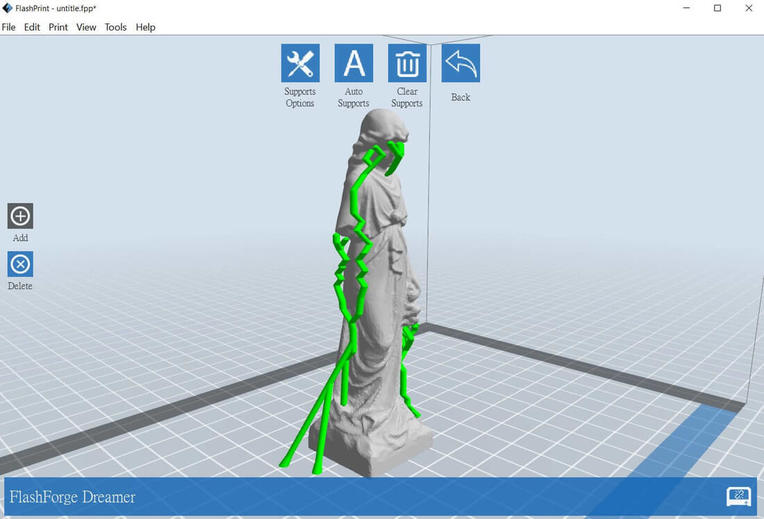

Linear support will be added if the overhang angle of the 3D model is larger than the angle you set.

2. Pillar Size

If you want the linear support to have a higher density, you should set a smaller value.

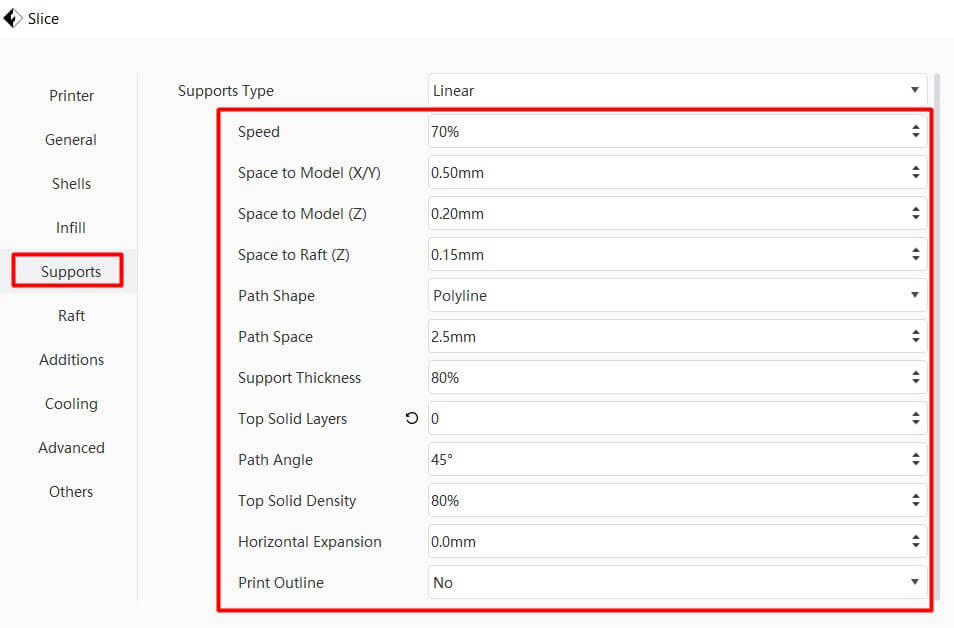

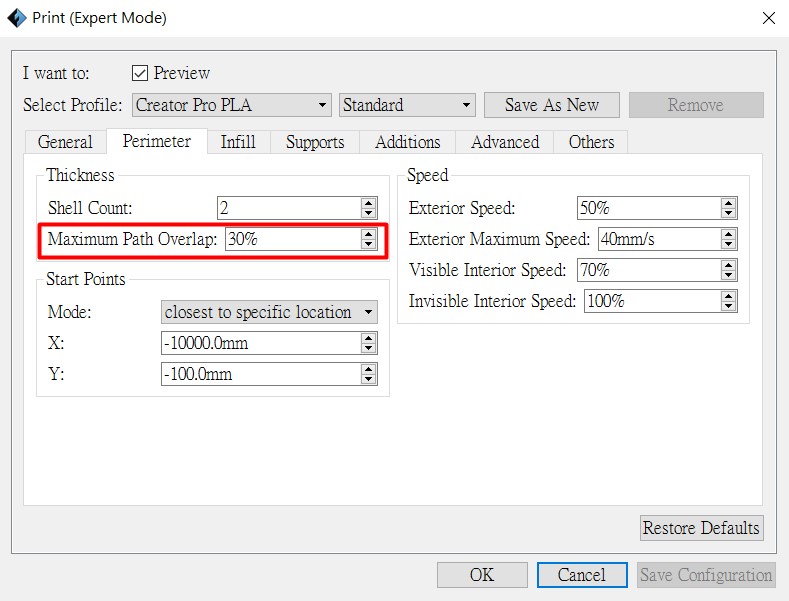

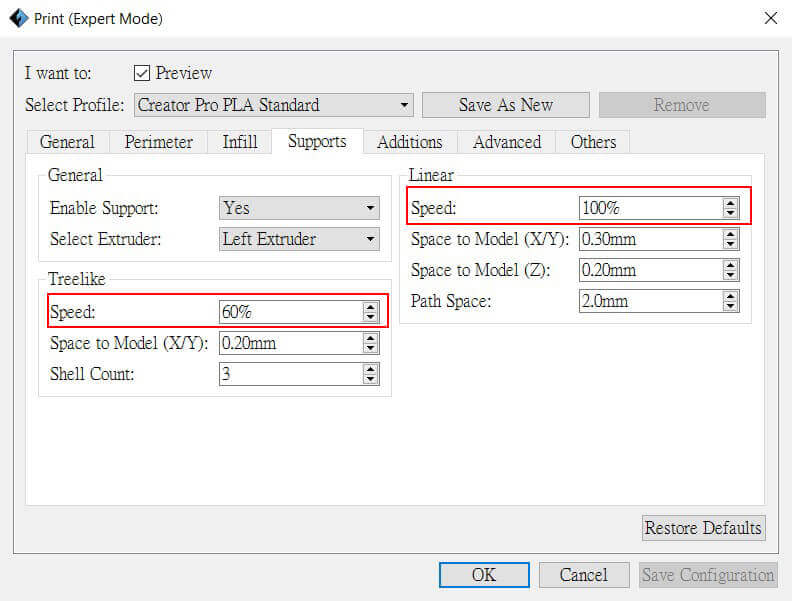

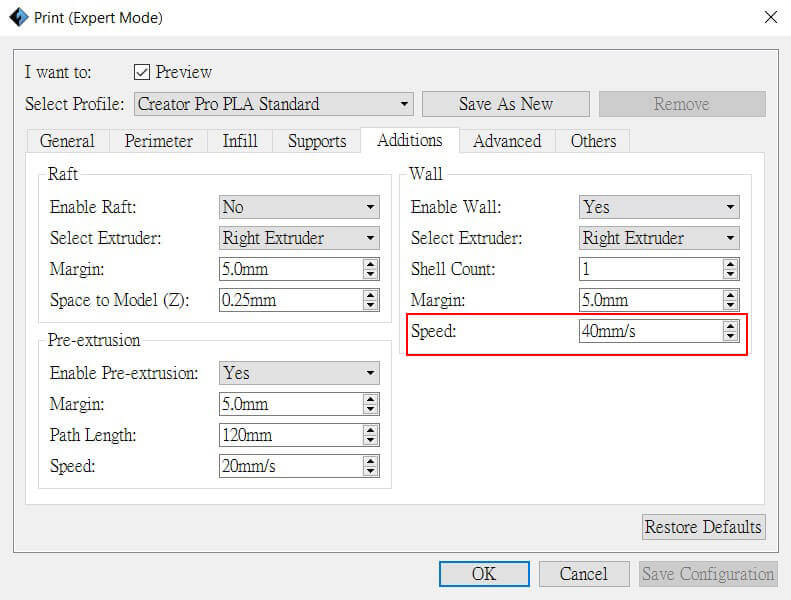

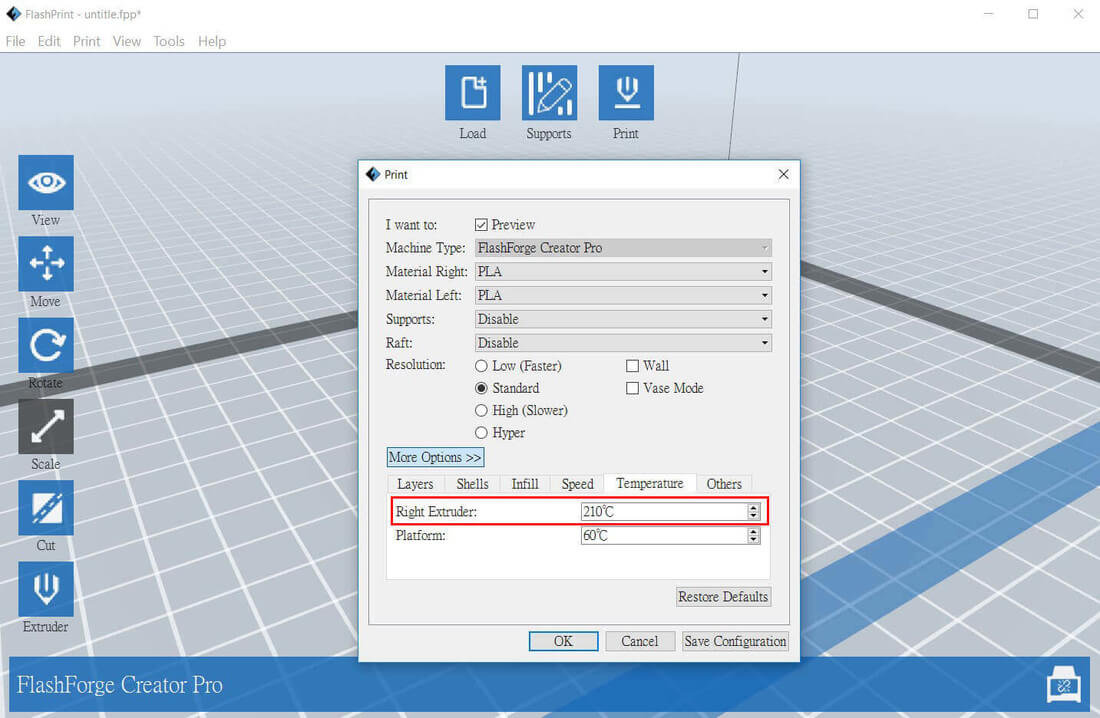

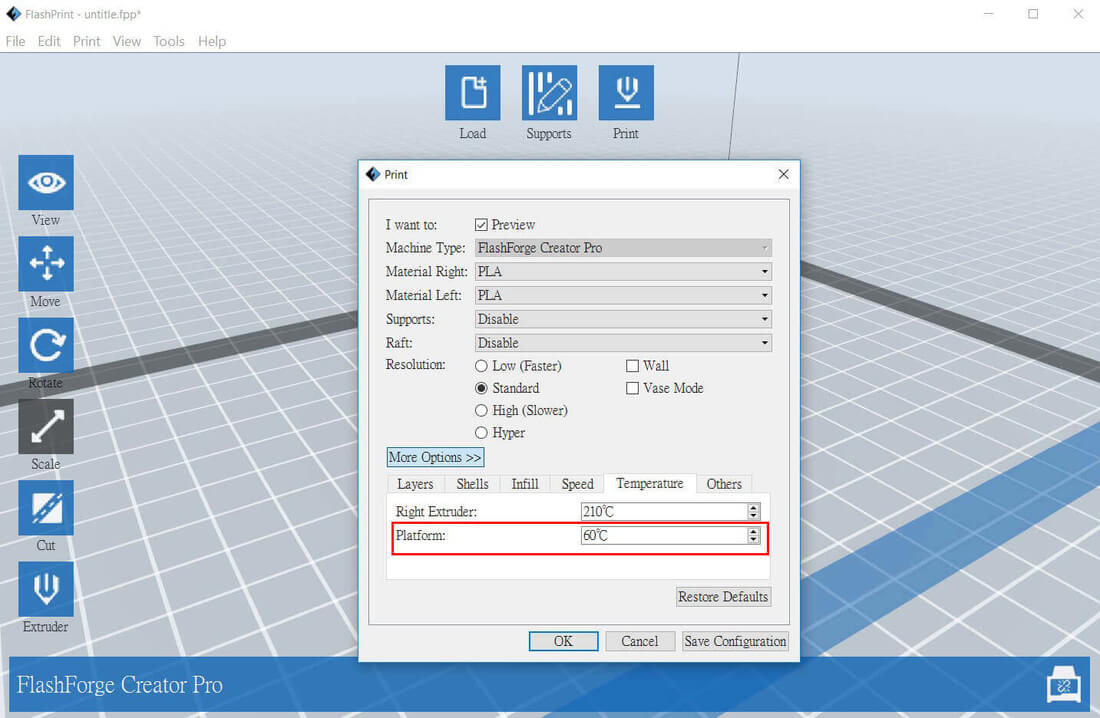

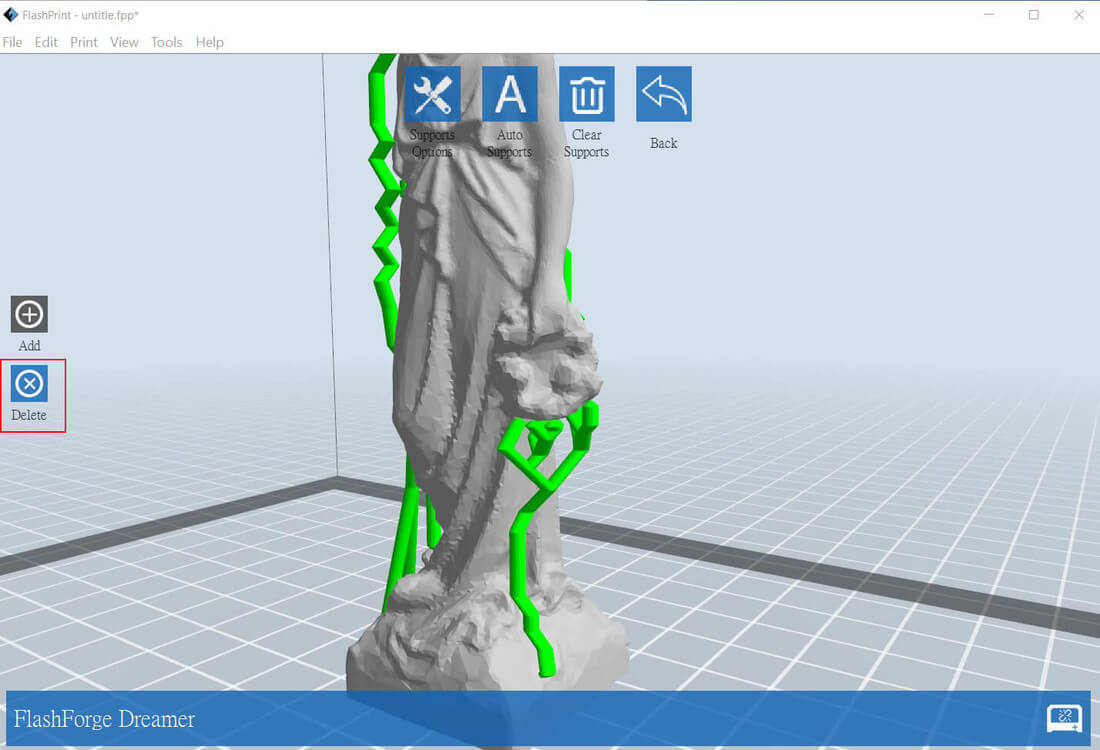

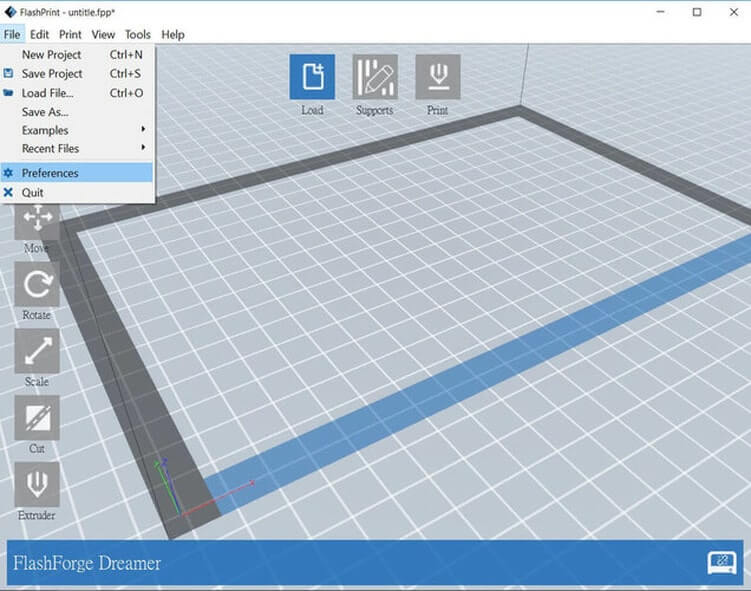

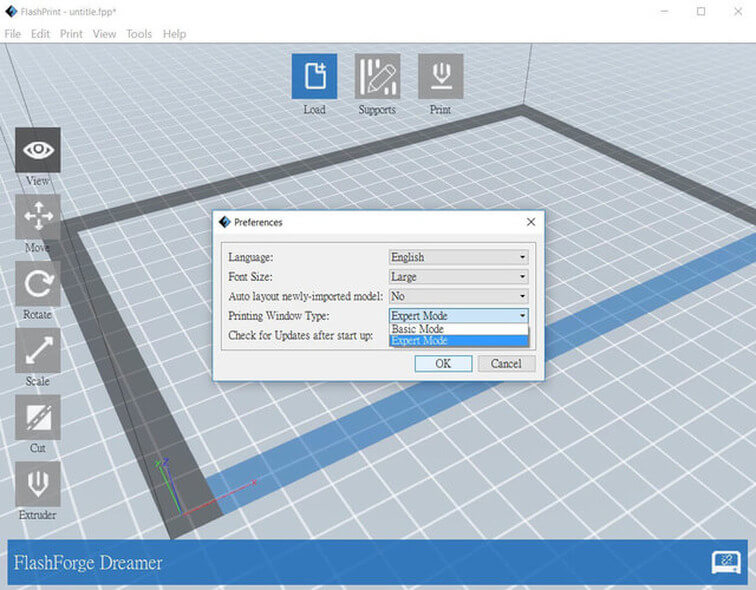

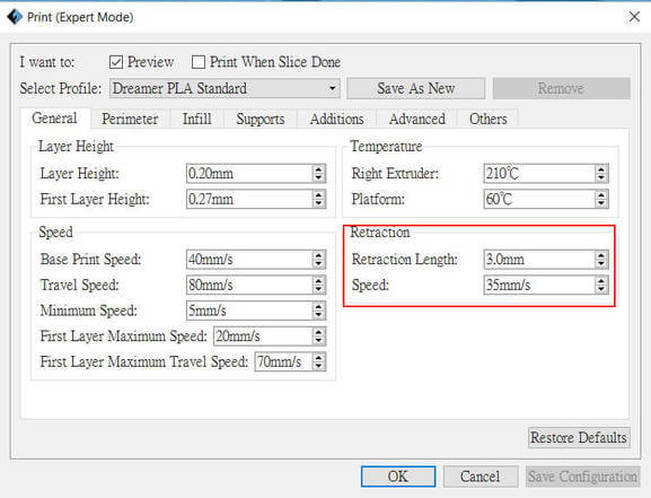

If you go into expert mode, more options will be available for linear support such as:

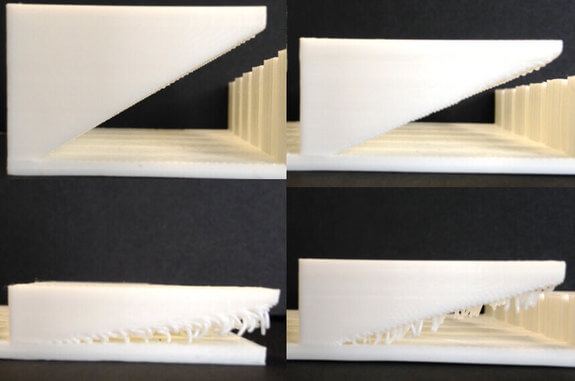

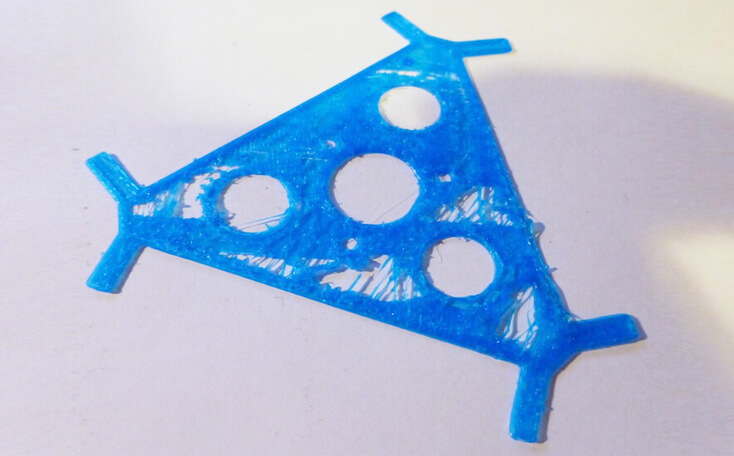

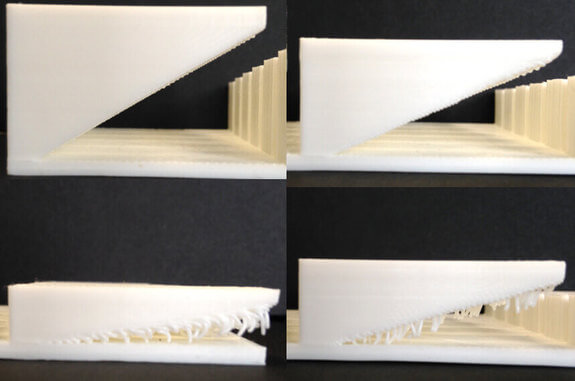

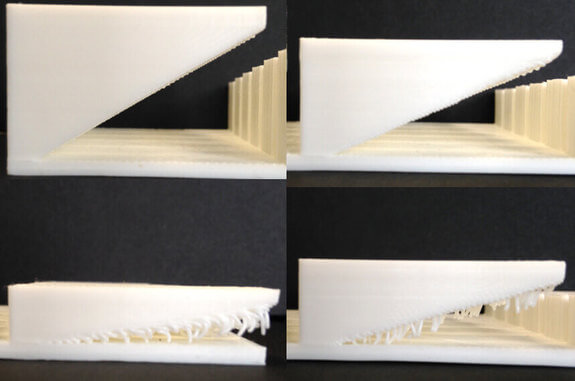

1. Space to Model (Z)

This is to decide the vertical space between the 3D model and the linear support. Bigger value means it will be easier to remove the linear support.

2.Path Space

This is similar to the Pillar Size settings space between adjacent support path, small path space will have a higher density of the linear support.

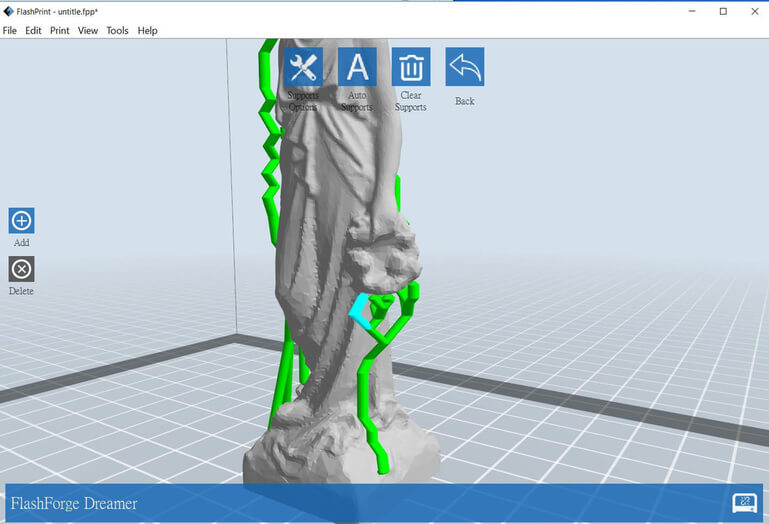

This is to decide the vertical space between the 3D model and the linear support. Bigger value means it will be easier to remove the linear support.

2.Path Space

This is similar to the Pillar Size settings space between adjacent support path, small path space will have a higher density of the linear support.

Other Article:

RSS Feed

RSS Feed