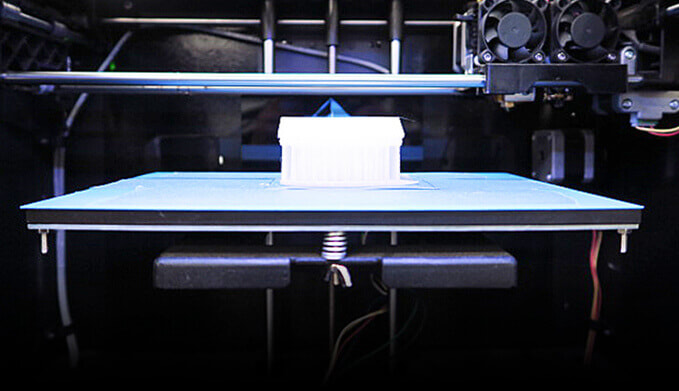

When doing a big 3D print, there are some 3D slicing settings we need to pay attention. Today we are going to talk about this:

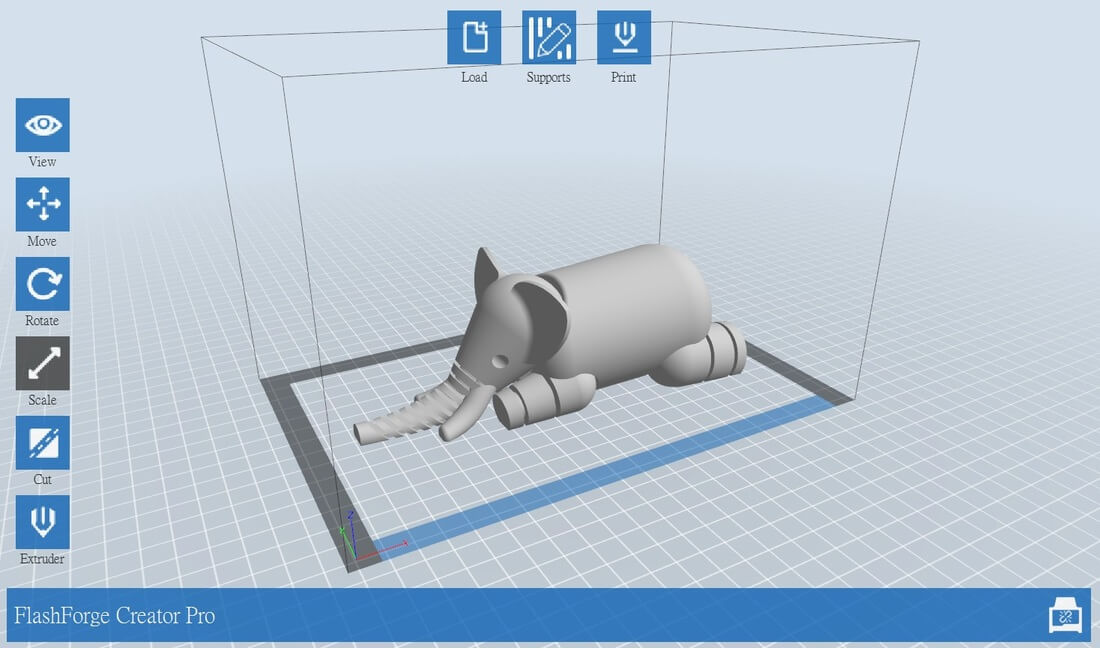

1.3D Printing Speed

Print with slower speed would be better if you find that the big 3D print can not attach on the build plate firmly. This setting can be set in the 3D slicing software Flashprint as following:

Print with slower speed would be better if you find that the big 3D print can not attach on the build plate firmly. This setting can be set in the 3D slicing software Flashprint as following:

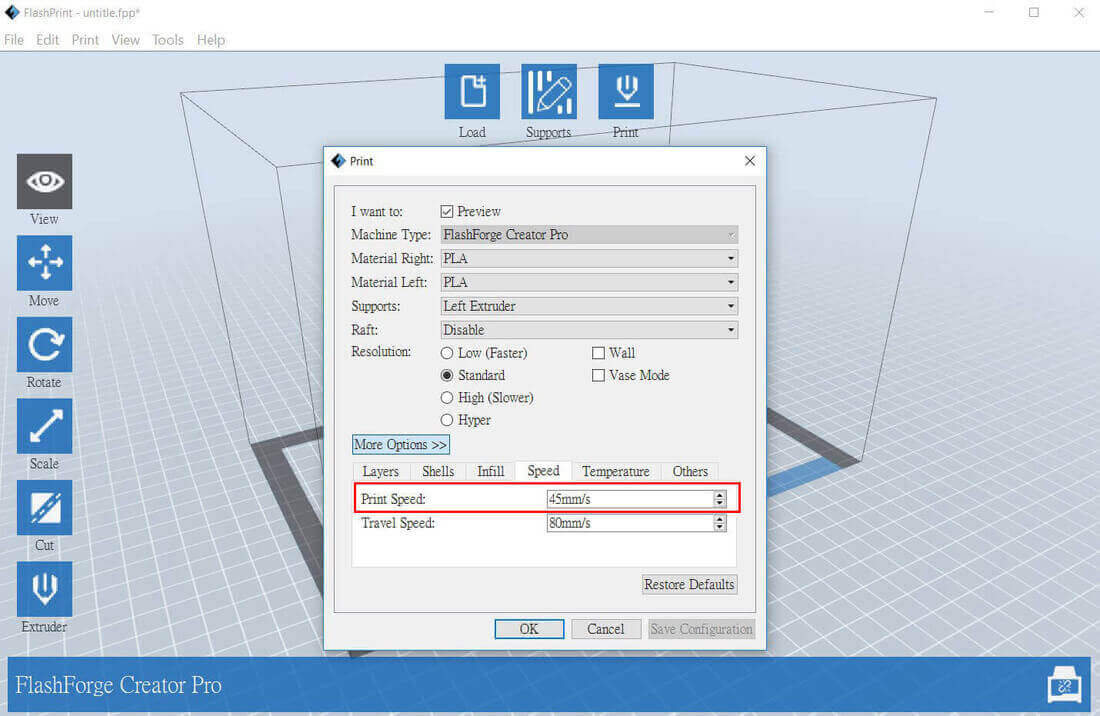

2. Temperature of the heat bed

if there is a heat bed in your 3D printer, please activate the heating function of your heat bed. With heat bed, the warping issues of the big 3D print can be minimized. Beware that the suitable temperature of the heat bed depends on what 3D printing filament you will use. Heat bed temperature in the Flashprint can be set as following:

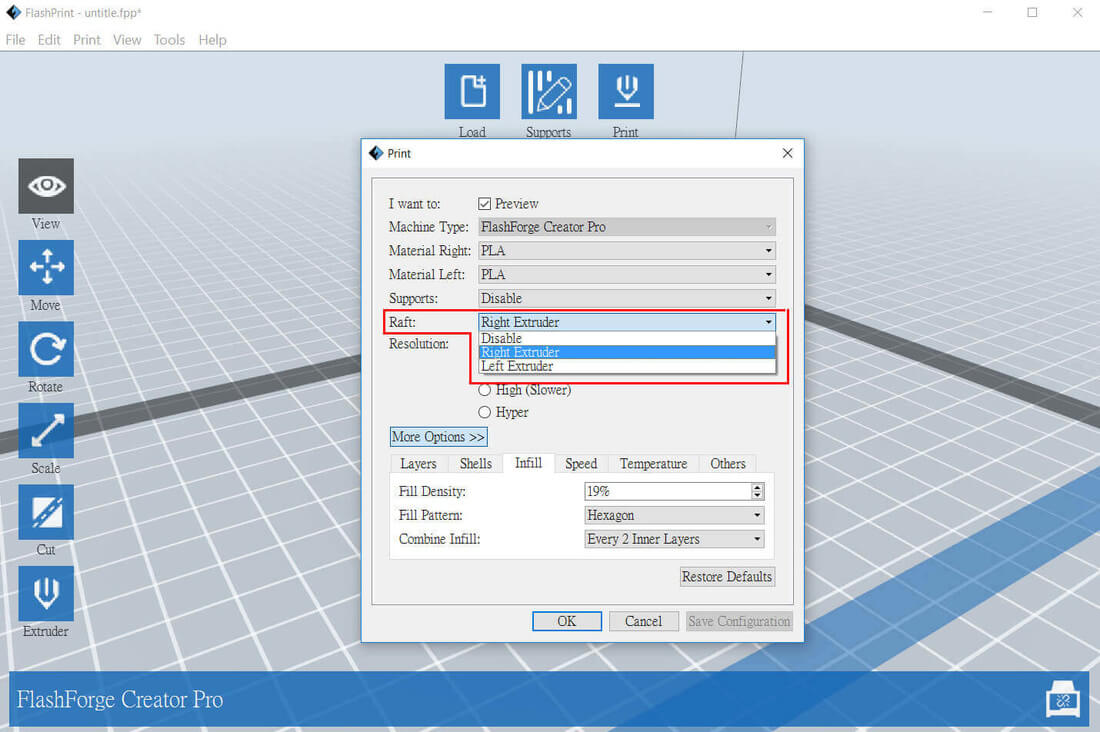

3. Using Raft / Brim

Warping issue easily occurs on the bottom part of the big 3D print, so sometimes it is better to add a raft or brim at the bottom of the 3D model, which can increase the 3d print adhesion on the build plate. In the Flashprint, raft can be added in the following way:

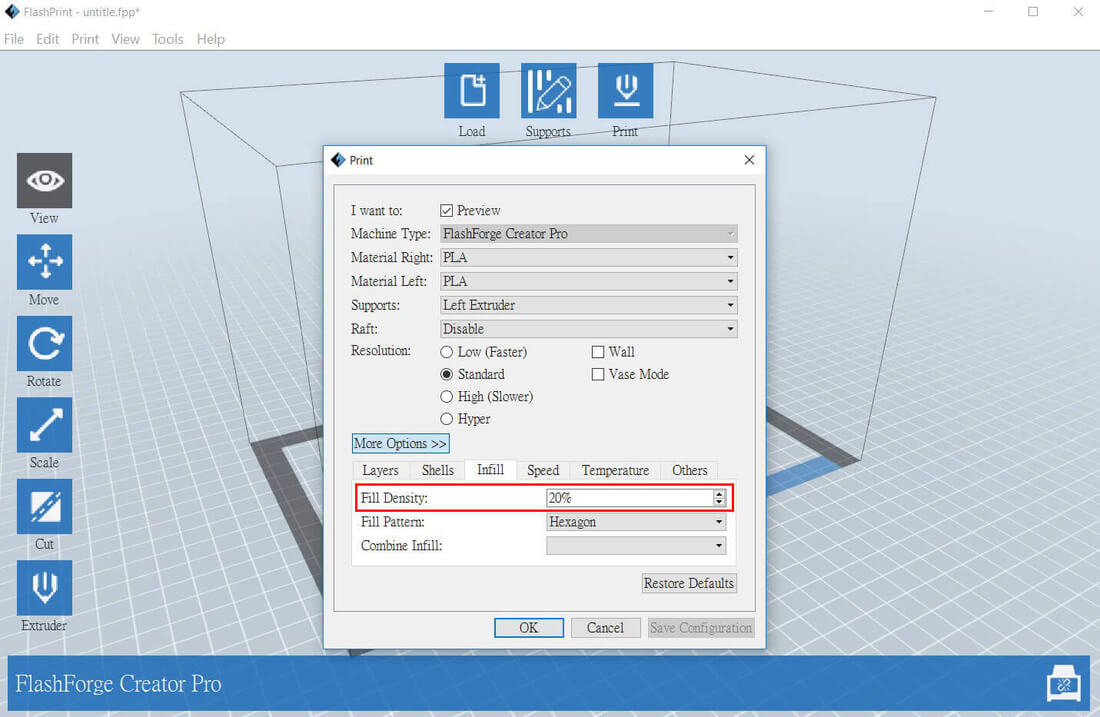

4 Infill density

It is better to have less infill density for the big 3D print, Lower the infill density can lower the warping possibility. It is because the higher infill density means that more contraction force will be created when the 3d print is cooling down.

Other Article:

RSS Feed

RSS Feed