You may encounter the situation that there is gap between 3D printout’s perimeter shells without overlapping. Today we will talk about what actions we should take to solve this issue.

1.Distance between nozzle and build plate

If the leveling was not done properly, there is chance that the distance between nozzle and build plate is too far, which could lead to a gap between the 3D printout’s perimeter shells without overlapping. Therefore, user should try to do the leveling again.

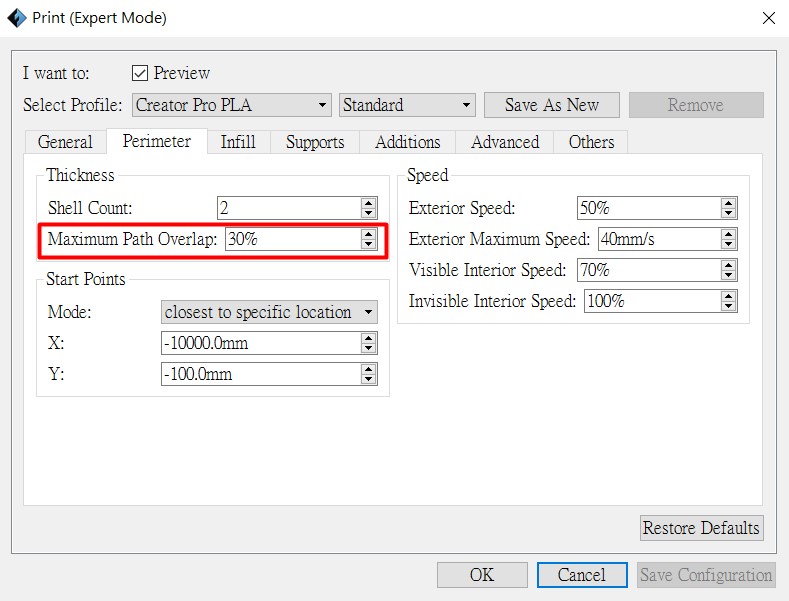

2. Perimeter shell overlap rate

User can try to adjust the 3D model’s perimeter shell overlap rate in the expert mode of the Flashforge's 3d slicing software Flashprint. Normally the overlap rate should be set to be 30%.

3. First layer height is too low

If setting the first layer height too low, there could be a gap without overlapping. Try to increase the first layer height and make sure the first layer height is bigger than layer height.

Other Article:

RSS Feed

RSS Feed