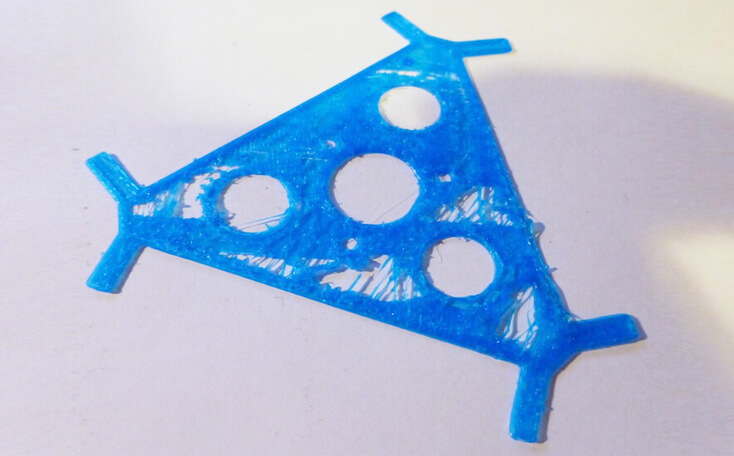

Sometimes you may encounter a situation that a 3D model cannot attach on a print bed firmly. Actually there are some settings in a 3D slicing software that can improve the print bed adhesion.

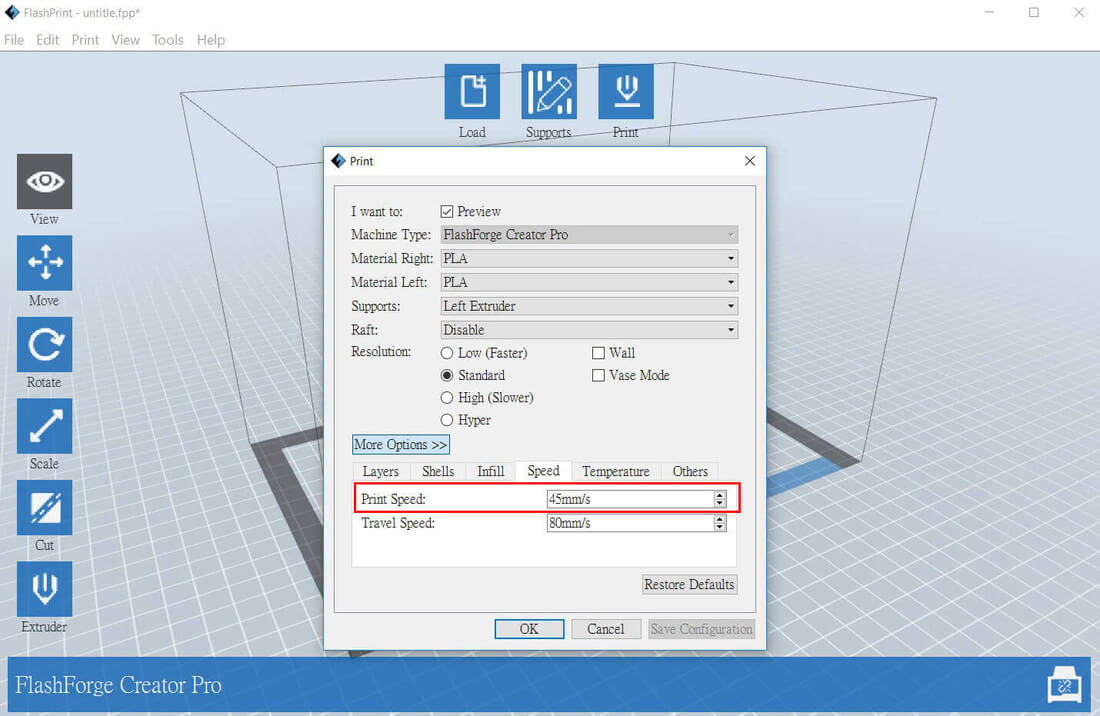

First is the printing speed. If we slower down the printing speed, a 3D printout will be able to attach on the print bed more firmly. If you are using Flashprint, you can do this setting as following:

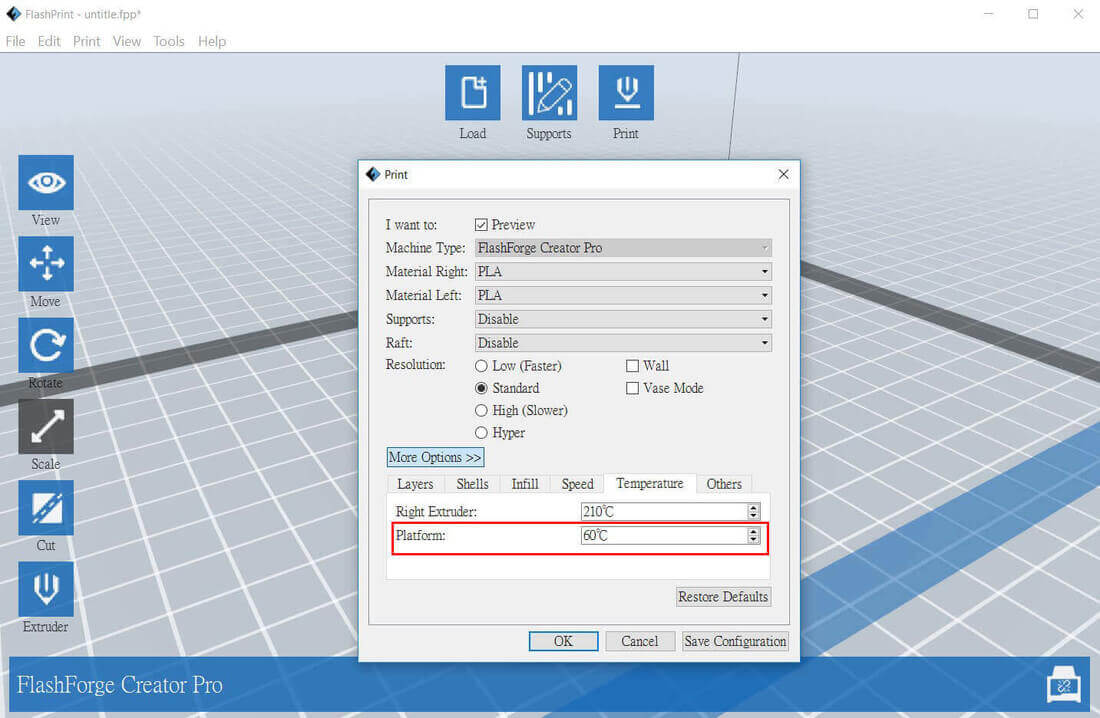

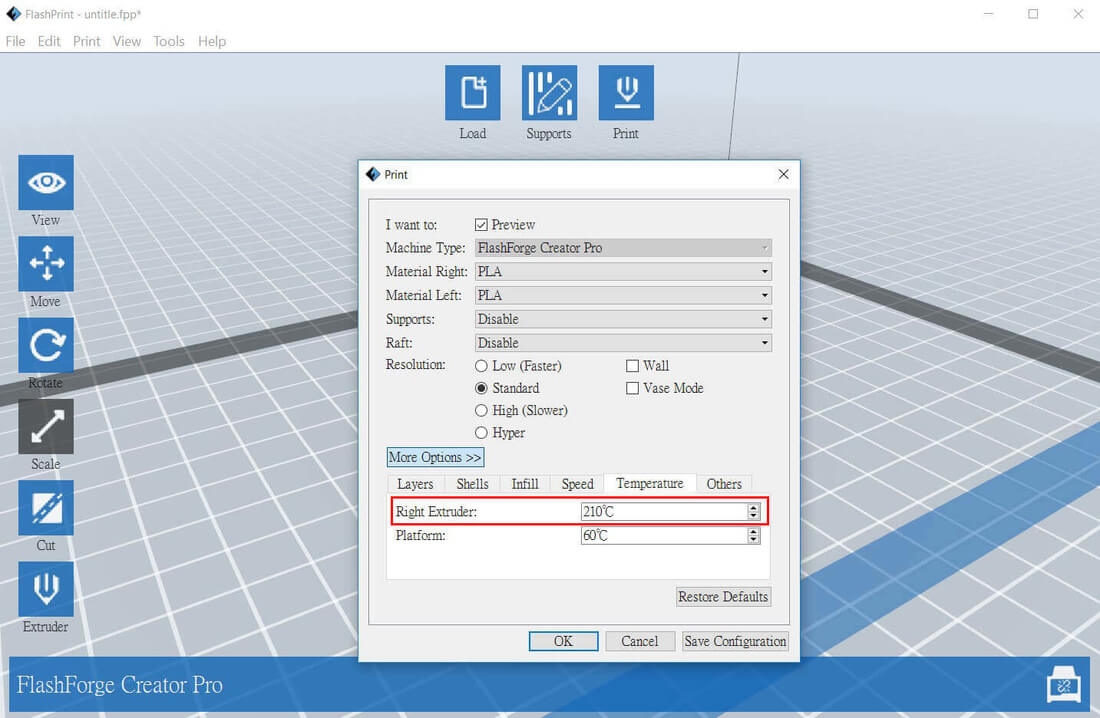

Second is to increase the temperature of the print bed if your print bed has heating function. Increasing the heat bed temperature can improve the print bed adhesion, and for each printing material, the suitable temperature for the heat bed will be different. If you are using Flashprint, you can adjust the print bed temperature as following

Another setting is to adjust the extruder temperature. If we increase the extruder temperature, the printing filament will become more liquefied, which can help improve 3D printer's print bed adhesion.

Other Article:

RSS Feed

RSS Feed