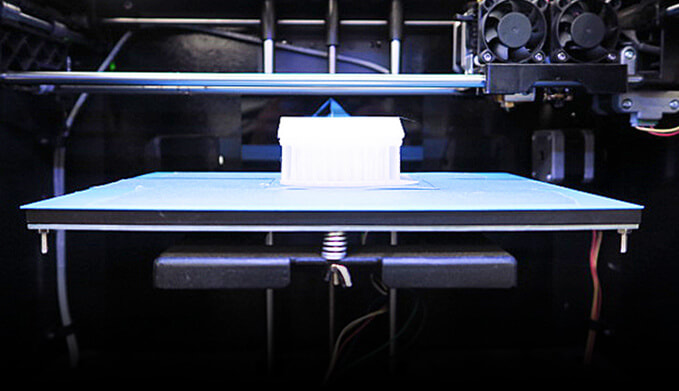

If you want to have a dual 3D print, there will be a wall(purge wall ) function for you to choose. The wall function will be used when you need to have a dual print, so what is the function of the wall?

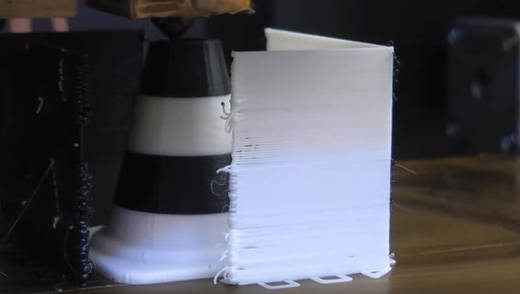

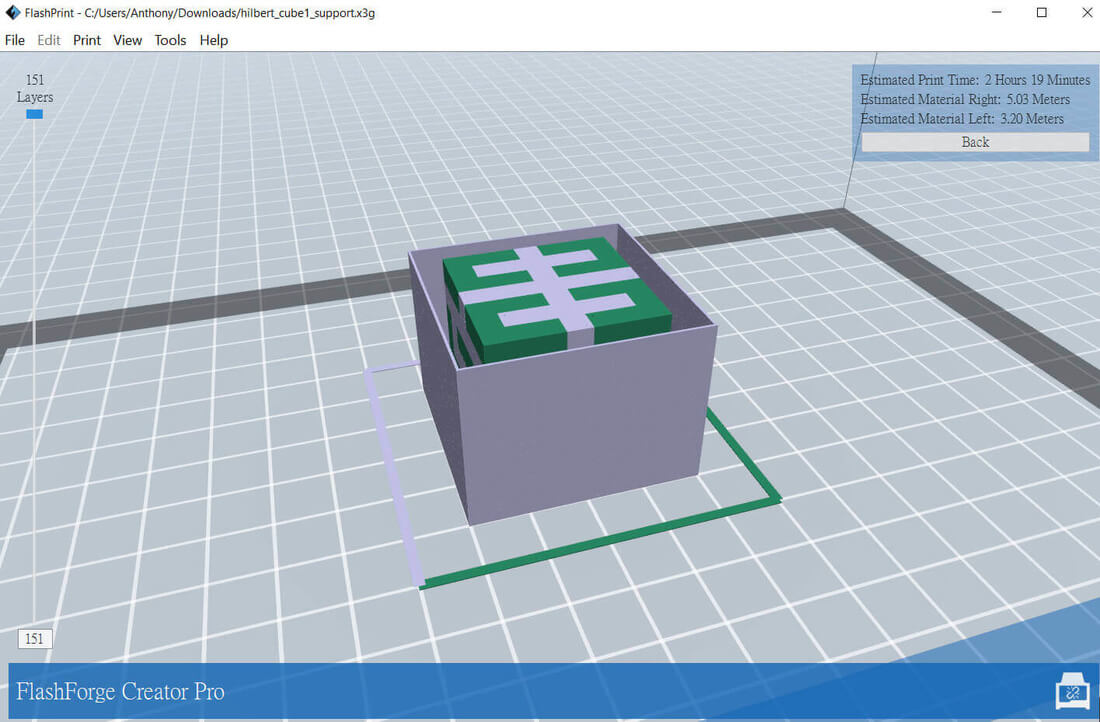

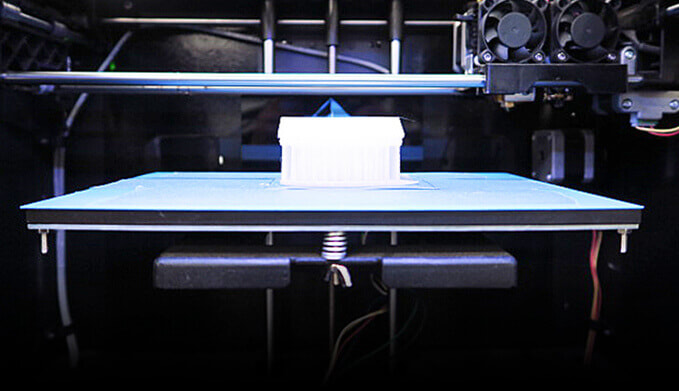

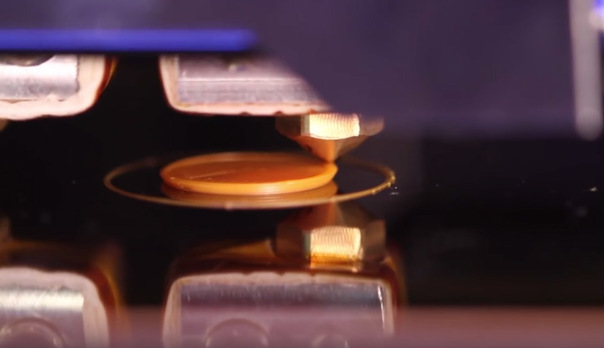

If you activate the wall function, there will be a wall printed around the 3d model as shown in the above picture. The reason to use wall function is to minimise the oozing issue.

When having dual 3D print, one nozzle will squeeze out plastic while another nozzle will stand by, but the one which is standing by continues in very hot status, so the plastic inside will be melted down and possibly result in oozing. If the wall function is activated and there is a wall surrounding the 3D model, the nozzle which has oozing can leave the melted plastic onto the wall when the nozzle passes through and touches the wall.

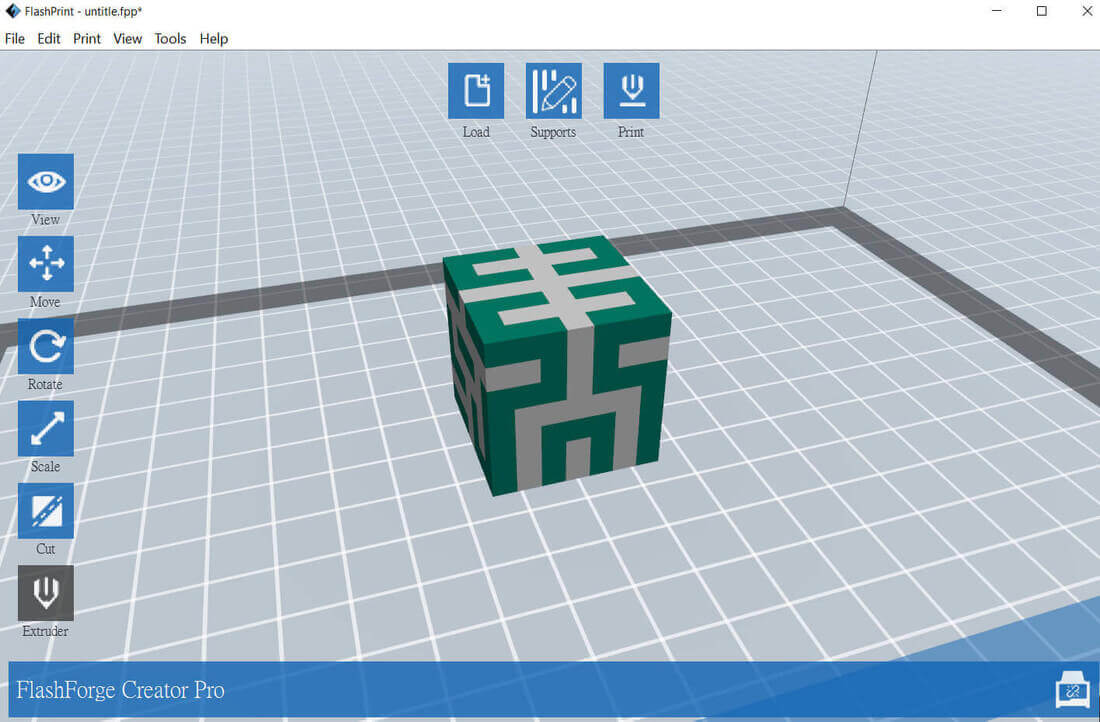

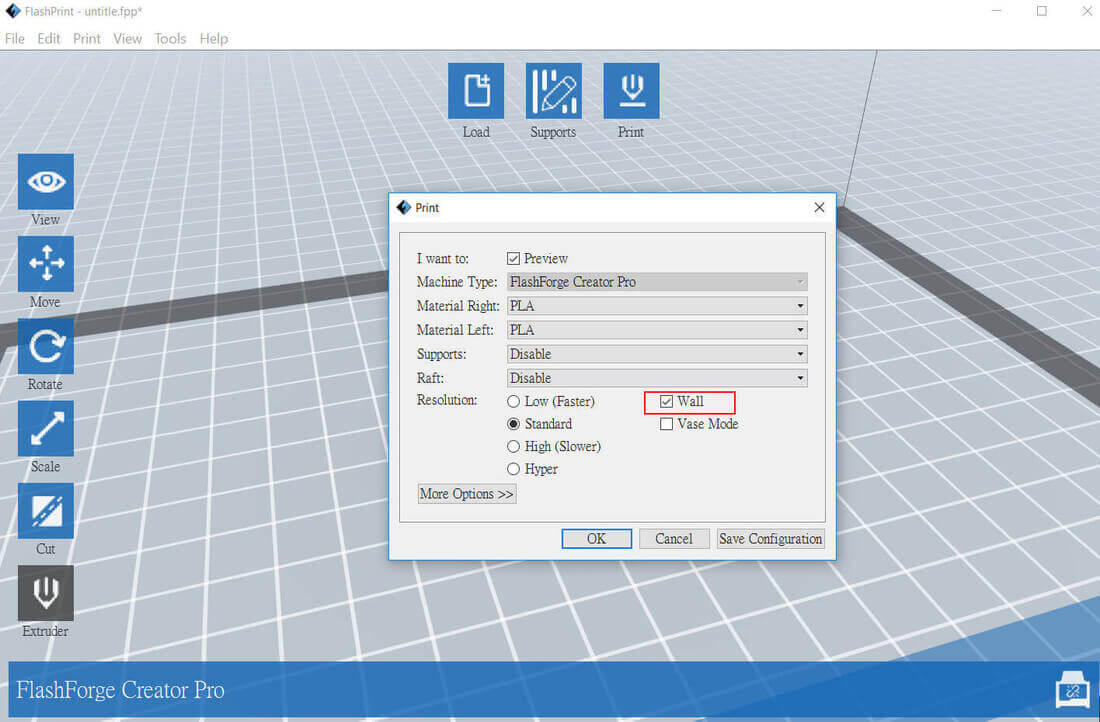

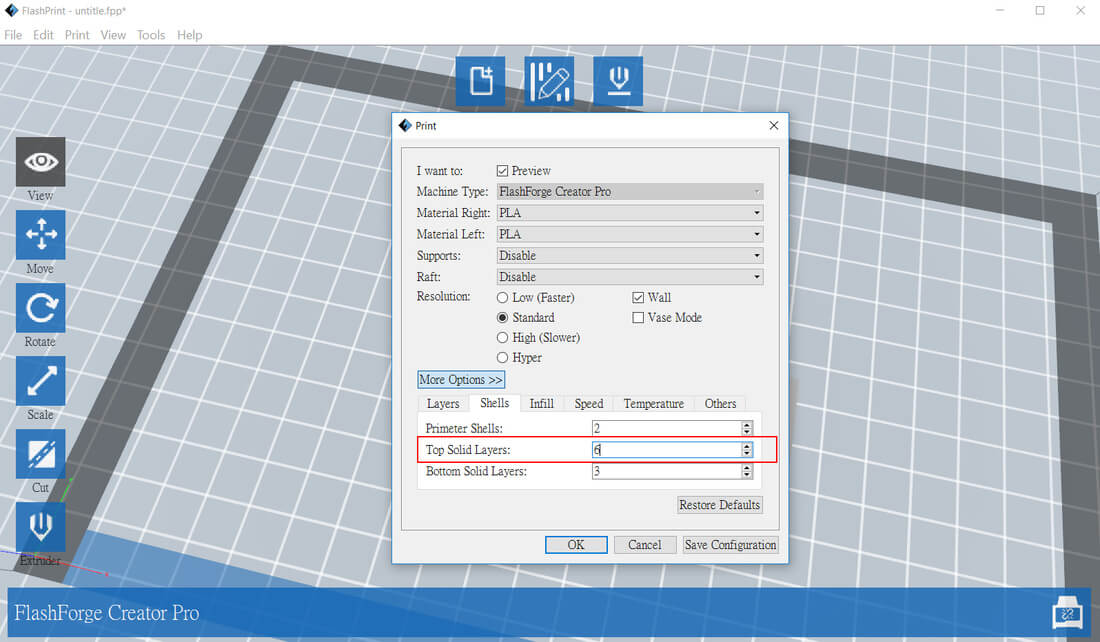

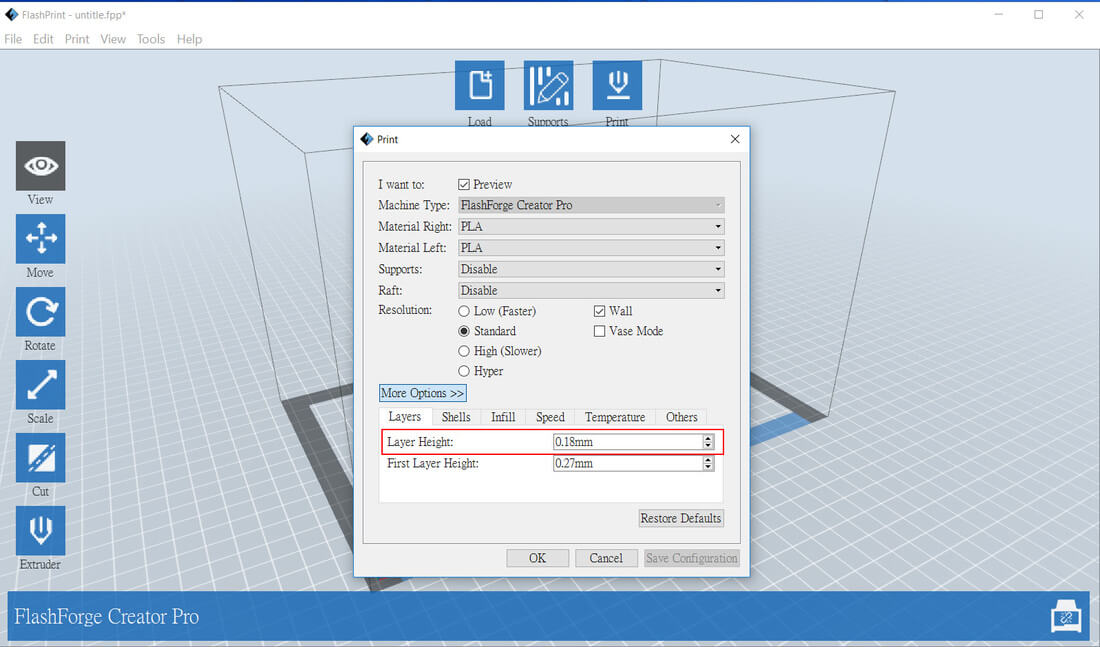

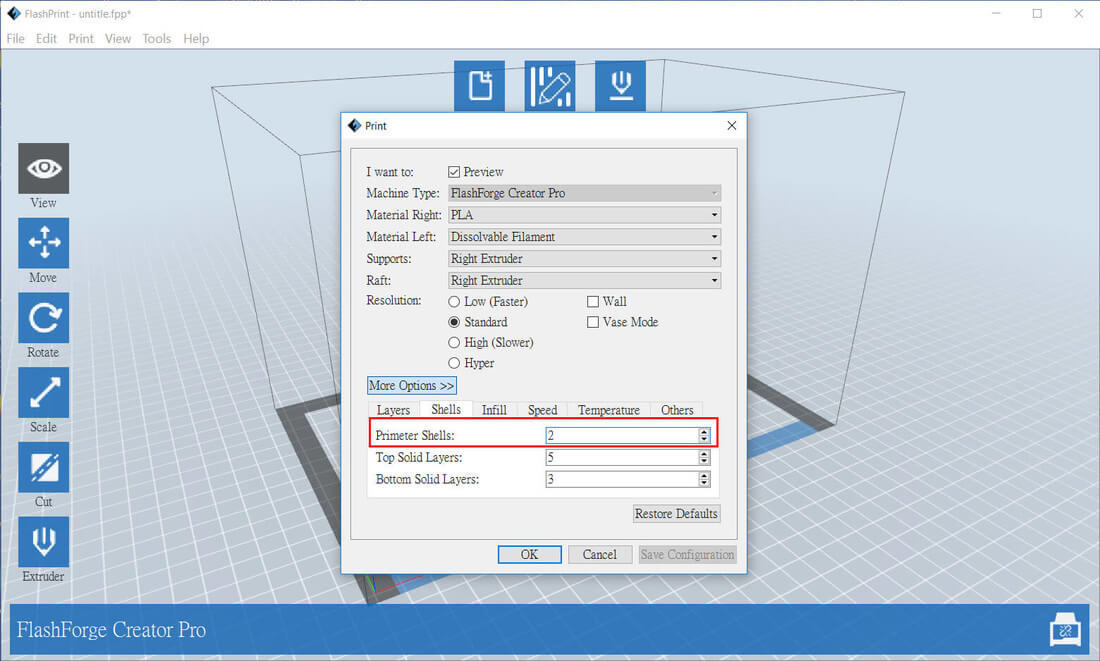

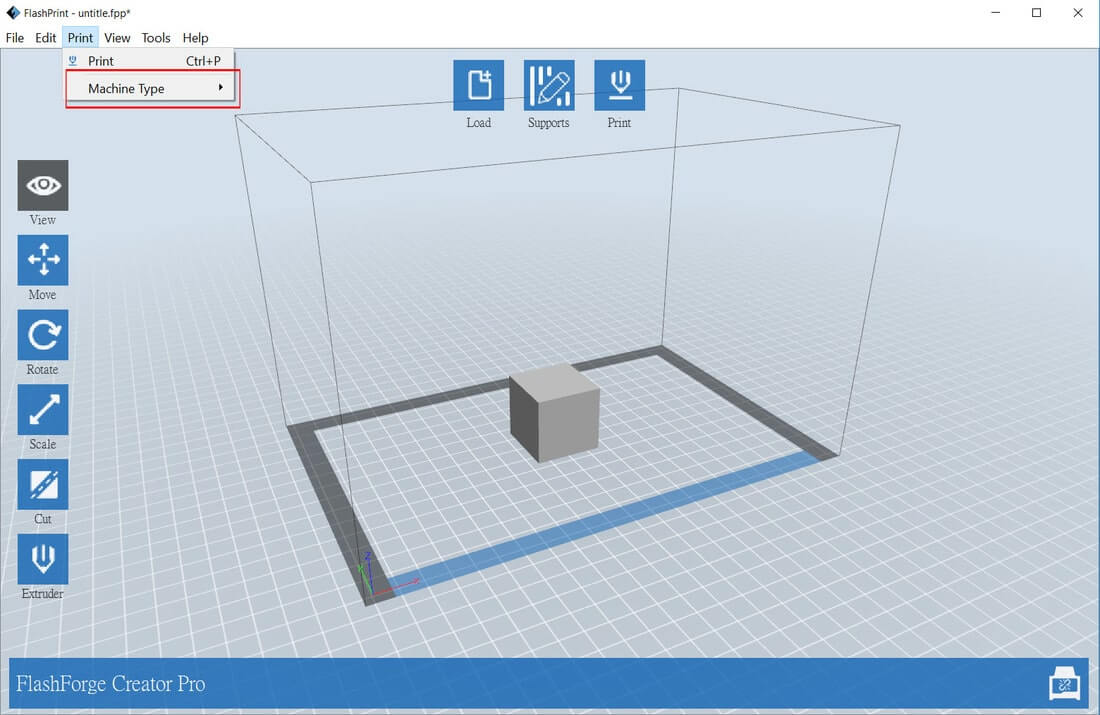

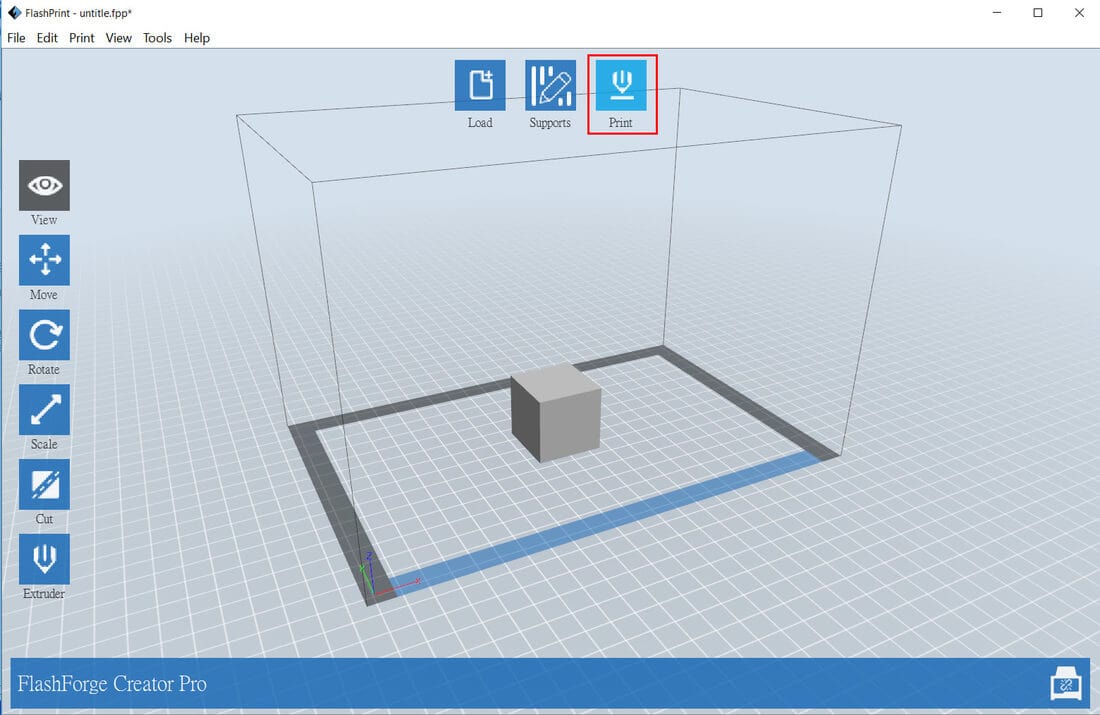

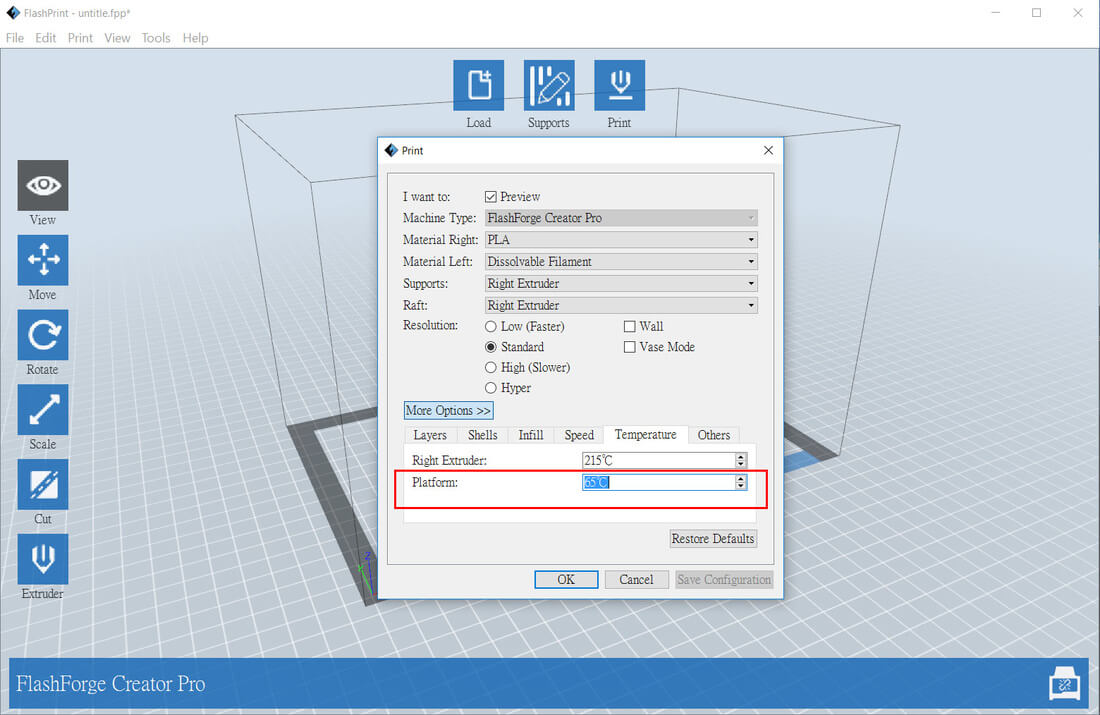

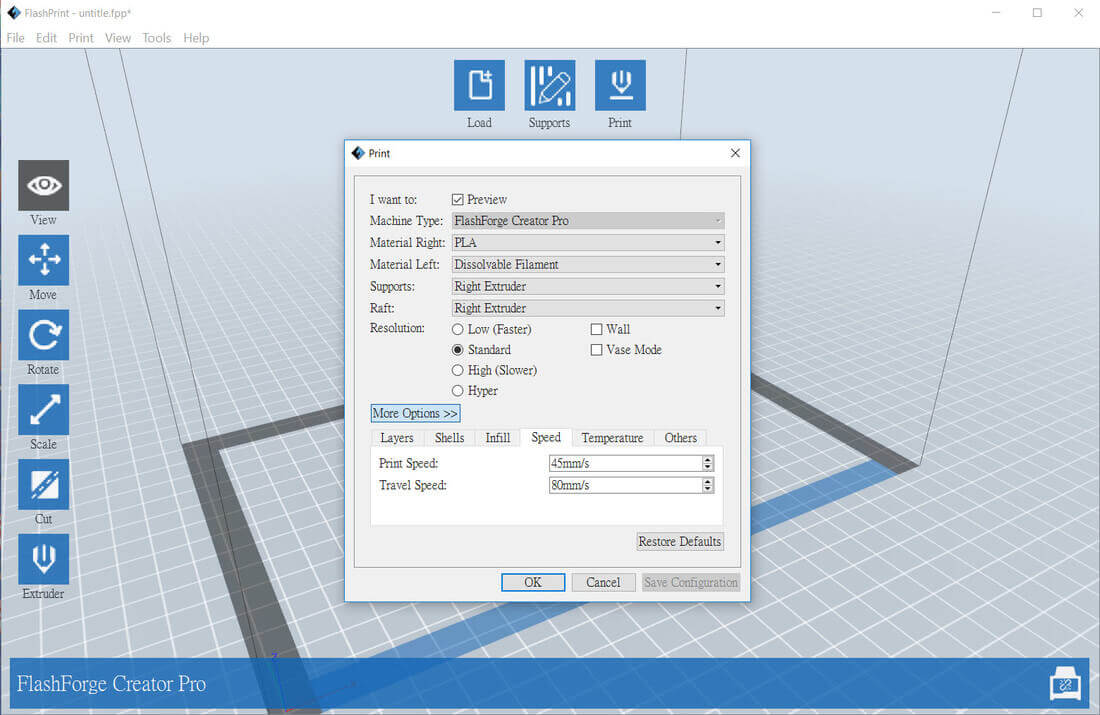

The following is to demonstrate how to use the Flashforge's 3D slicing software Flashprint to set the wall:

Other Article

RSS Feed

RSS Feed