In the 3D slicing software, Top Solid Layer setting can affect the quality and outlook of the 3D printout. Top solid layer setting is about how many solid layer will be printed onto the top of the model. As we mentioned in the previous articles before, when printing the inner structure of the 3D model, infill with chosen pattern and density will be used, and the top solid layer will be printed on the top of those infill. If the number of the top solid layer is not enough, the infill will be exposed and can be seen from outside and result in what we called pillowing phenomenon as shown below:

Although the lack of enough fill density will also lead to pillowing, how many top solid layers are enough to cover those infill to avoid the pillowing? General speaking, it is safer to set the number of top solid layers to be 6. However, the more top solid layers you set, the longer time the 3D printing will take.

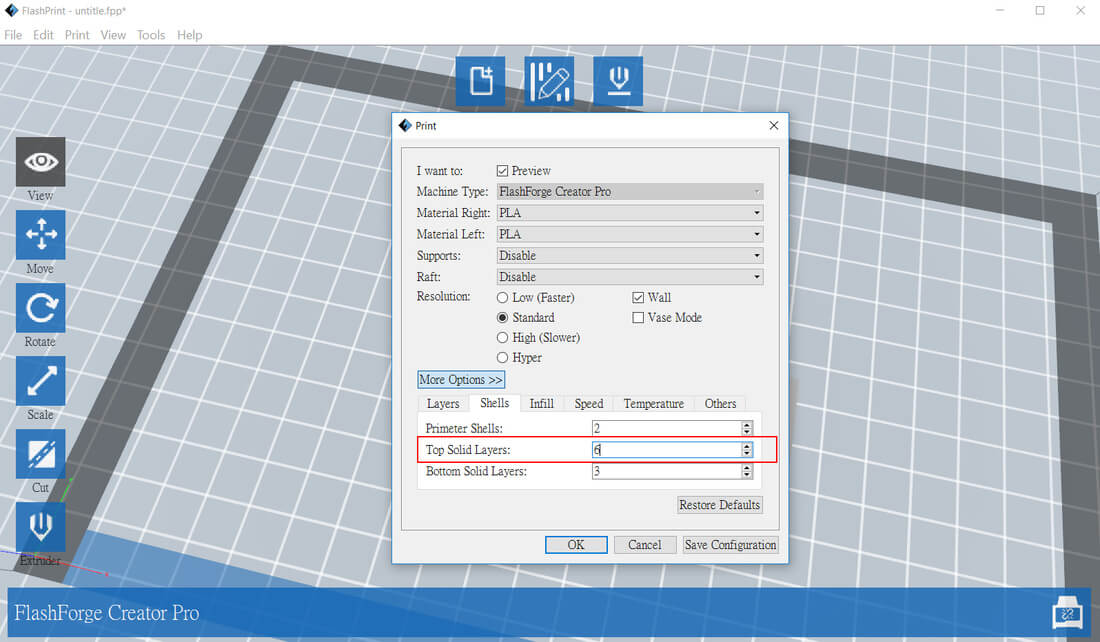

The following is how to set the number of top solid layer in the 3D slicing software Flashprint:

The following is how to set the number of top solid layer in the 3D slicing software Flashprint:

RSS Feed

RSS Feed