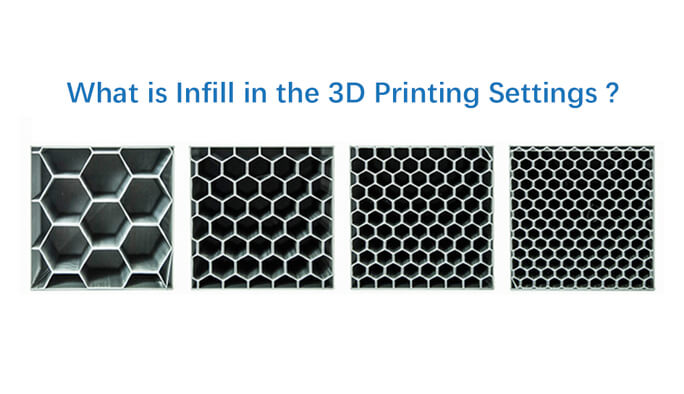

Higher fill density will lead to the harder 3D printout. If the infill density is 100%, the printout will a solid model. On the contrary, if the fill density is 0%, the printout will be hollow. In general, the density of the infill within 15% -30% is good enough to provide the printout with a reasonable hardness. On the other hand, the higher the infill density, the longer the printing time is required.

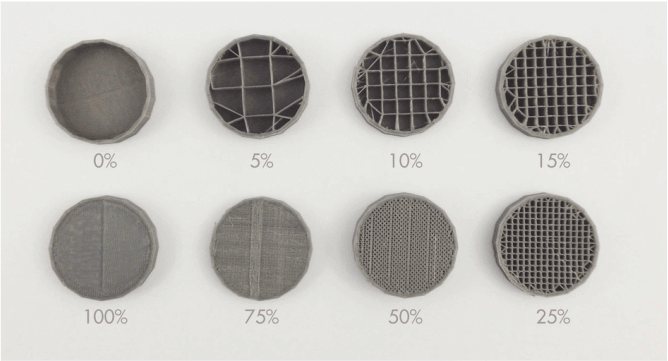

Fill pattern (Infill pattern)

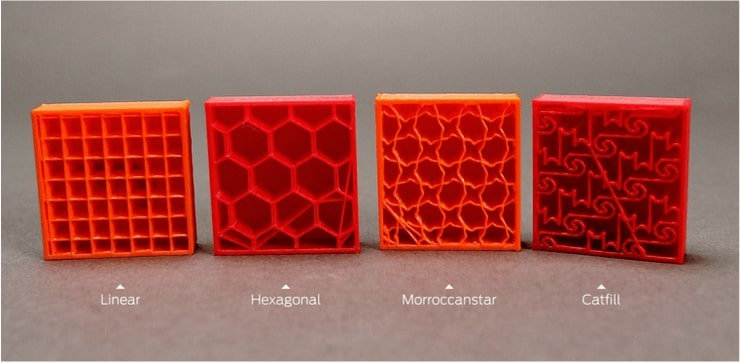

It is very easy to set the infill pattern in the 3D slicing software as well. Generally there are several options of the infill patterns such as hexagon, linear etc.. If you want to print faster, linear infill pattern is preferable and if you want to have a stronger printout, hexagon is better.

To do the setting of infill pattern and infill density in the 3D slicing software Flashprint which was developed by Flashforge, just go to the "infill“ menu and type in the percentage of the infill and choose its pattern as shown below:

RSS Feed

RSS Feed